Advance Steel for the Prefab Edge

Some people think of it as the LEGO® of modern construction-Advance Steel can turn complex structures into simple, snap-together solutions. Just as those iconic bricks empower limitless creativity with precision and ease, Autodesk Advance Steel brings the same magic to steel fabrication and prefabrication. In a world where time is tight and accuracy is everything, this 3D modelling software helps teams build smarter, faster and stronger-one perfectly crafted piece at a time, restructuring prefabricated modular buildings, brick by digital brick.

What Is Advance Steel?

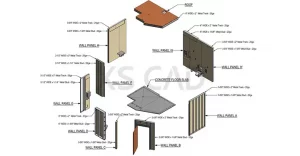

Advance Steel is a 3D modelling and detailing tool built specifically for steel fabrication and installation. It enables engineers, fabricators and detailers to work together in a seamless BIM workflow. By automating complex processes and streamlining communication, Advance Steel helps reduce rework, improve coordination and deliver prefabricated construction projects on time and on budget. Using Advance Steel, teams can:

Powerful Features to Simplify Complexity

Steel Modelling Capabilities

Detailing & Documentation

Seamless Interoperability

Advance Steel is designed to work hand-in-hand with other Autodesk tools and industry platforms, enabling smooth data exchange across disciplines:

The Future of Fabrication

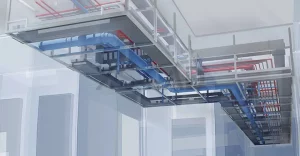

The rise of modular prefabrication has transformed how buildings are delivered-and steel is at the heart of this shift. With its strength, durability and adaptability, steel forms the structural backbone of many modular systems. But to meet the speed and precision required for off-site fabrication and steel detailing services, traditional methods fall short. This is where Advance Steel shines.

How Advance Steel Enhances Modular Fabrication

Why Choose Advance Steel?

Advance Steel is a full-spectrum solution to support workflows from concept through construction. Key benefits include:

Just as LEGO® bricks empower builders of all ages to bring imaginative structures to life with flawless interlocking pieces, Advance Steel brings that same elegant simplicity to the complex world of prefabrication. By translating architectural vision into precise, prefabricated components, it ensures that each steel member fits seamlessly into place-reducing errors, saving time and boosting collaboration. In an industry racing toward smarter solutions, Advance Steel proves that building with steel can be as intuitive and efficient as snapping together a masterpiece, one digital ‘brick’ at a time.

Axium Global can provide expert steel fabrication and steel detailing services for leading global architects, consultants and contractors using trusted 3D modelling software. Our range of services include creating structural steel detailing, steelwork detailing, 3D BIM models, BIM coordination, MEP design drafting and 2D and 3D design for prefabricated modular buildings and other prefabricated construction. We also provide modular prefabrication design support services by using BIM software programs, such as Autodesk Advance Steel, Revit, Dynamo for Revit and 3ds Max, V-Ray, SketchUp, Adobe Photoshop and After Effects, Illustrator while using BIM Collaborate Pro .